from the intricate planet of plumbing and HVAC programs, the enlargement tank frequently operates at the rear of the scenes, diligently managing strain fluctuations to safeguard the entire infrastructure. While seemingly basic, its position is crucial, and its longevity straight impacts method performance and upkeep fees. Have you ever at any time thought of what definitely helps make an expansion tank endure the check of time? outside of the Preliminary cost tag, the true price lies in its power to perform reliably, yr after 12 months. From product selection to style and design issues and appropriate routine maintenance procedures, we are going to uncover the tricks to maximizing the existence within your growth tanks.to be a filter tank company, we comprehend the value of higher-quality supplies and precision engineering in extending the lifespan of critical components like enlargement tanks. Whether you’re an engineer, contractor, or facility manager, this complete guide will deliver precious insights on maximizing method performance and decreasing very long-phrase operational prices.

Table of contents:

the muse: materials Selection and Corrosion Resistance

design and style Matters: Structural Integrity and Internal Components

The artwork of Manufacturing: Precision and Quality Regulate

Environmental aspects: Understanding the working circumstances

The Importance of servicing: Proactive Steps for Longevity

criteria and Certification: making certain Compliance and high quality

The Foundation: content assortment and Corrosion Resistance

The elements used in the construction of an enlargement tank are the very first line of protection towards untimely failure. the choice procedure just isn't almost Price; It can be about matching the material to the precise running ecosystem along with the fluid it is going to consist of. let us investigate the critical components:

Tank Body content:

stainless-steel Grades: The Gold Standard: Stainless steel, particularly grades like 304, 316, and duplex stainless steel, is often the popular choice for expansion tanks on account of its inherent corrosion resistance. Every grade offers various amounts of security versus precise corrosive brokers. For illustration, 316 chrome steel is made up of molybdenum, which boosts its resistance to chlorides, which makes it ideal for coastal environments or programs working with dealt with drinking water. comprehending the specific h2o chemistry with your technique is essential for choosing the right stainless steel quality.

Carbon Steel with Protective Coatings: A Cost-efficient option: Carbon metal can be quite a practical solution if paired with a strong protective coating. The efficiency of this method hinges on the standard and software of your coating. Epoxy resins and polyurethane coatings are generally utilised, but their extensive-time period general performance is dependent upon components like coating thickness, adhesion into the steel area, and resistance to abrasion and chemical degradation. common inspection and upkeep with the coating are necessary to protect against corrosion from using keep.

Lined Tanks: an additional Layer of security: For highly corrosive fluids or Extraordinary running read more conditions, enlargement tanks with internal linings supply yet another layer of protection. resources like rubber, PTFE (Teflon), or specialized polymers can make a barrier between the fluid and the tank's metallic composition, preventing corrosion and extending the tank's lifespan. The choice of lining substance should be cautiously matched to the precise fluid remaining dealt with.

The Integrity of Welds:

Weld excellent: a sequence is simply as Strong as Its Weakest hyperlink: the caliber of the welds is paramount. Weak or improperly executed welds could become details of failure, resulting in leaks and even catastrophic rupture. elements like welding technique, filler product choice, and the skill with the welder all lead to weld integrity.

Non-harmful screening (NDT): guaranteeing concealed Flaws are Detected: NDT approaches, for example radiographic testing (X-rays), ultrasonic testing, and magnetic particle screening, are essential for detecting hidden flaws in welds. These exams can reveal cracks, porosity, along with other imperfections that might compromise the tank's structural integrity. employing a demanding NDT software is often a crucial expense in long-phrase trustworthiness.

Sealing and Fastening:

Seal components: avoiding Leaks and keeping stress: The selection of seal components, for instance O-rings and gaskets, is vital for blocking leaks. The seal product has to be appropriate with the fluid getting handled and capable of withstanding the working temperature and pressure. common substitution of seals, as Component of a preventative upkeep system, is essential for keeping procedure integrity.

Fasteners and Connections: stopping Corrosion-Induced Failure: The supplies employed for fasteners, for instance bolts and screws, need to even be corrosion-resistant. stainless-steel fasteners will often be desired, specifically in outside or humid environments. right torqueing of fasteners is also essential to make sure a secure connection and stop loosening eventually.

structure Matters: Structural Integrity and inside Components

Beyond product assortment, the look of your growth tank plays a significant part in its lifespan and durability. A properly-developed tank minimizes anxiety, stops corrosion, and makes certain the reputable purpose of inside factors.

Structural design and style: reducing tension and tiredness:

anxiety Concentration: Identifying and Mitigating Weak factors: Sharp corners, abrupt variations in geometry, and badly intended supports can develop parts of superior tension concentration. These parts are vulnerable to fatigue failure, Specially underneath cyclical force loading. Finite element Evaluation (FEA) may be used to establish and mitigate pressure concentrations throughout the structure section.

Thickness Calculations: making certain satisfactory Strength: The thickness from the tank partitions and end caps should be cautiously calculated to withstand the utmost functioning pressure having an satisfactory security margin. These calculations have to take note of the fabric's tensile power, yield toughness, and corrosion allowance.

assistance constructions: furnishing Stability and cargo Distribution: The aid construction needs to be sturdy adequate to aid the load on the tank and its contents, along with any external hundreds, for instance wind or seismic forces. The aid design should also reduce stress within the tank partitions.

Internal design and style: Optimizing move and Preventing Corrosion:

circulation Baffles: Preventing Stagnation and Sediment Develop-Up: In some applications, circulation baffles are used to immediate the flow of fluid throughout the tank, avoiding stagnation as well as buildup of sediment. This is especially essential in techniques wherever the fluid is made up of particulate matter.

Diaphragms and Bladders: The Heart in the Tank's perform: growth tanks normally include diaphragms or bladders to independent the drinking water and air cushions. The material and design of such components are critical for their longevity. they need to be proof against the fluid currently being dealt with, along with the cyclical stress of growth and contraction. Regular inspection and substitute of diaphragms and bladders are often necessary.

Surface procedure: boosting Corrosion Resistance:

Blasting and Cleaning: Preparing the floor for Protection: area planning, such as sandblasting or shot peening, is important for making a cleanse and textured floor that encourages the adhesion of protecting coatings.

Passivation: boosting the Corrosion Resistance of Stainless Steel: Passivation is usually a chemical cure that improves the corrosion resistance of stainless steel by forming a skinny, protective oxide layer about the surface area.

The Art of producing: Precision and excellent Manage

The production process is the place the look principles are introduced to daily life. Precision, high-quality Management, and adherence to field expectations are paramount for ensuring the extensive-expression trustworthiness of enlargement tanks.

product slicing: Precision and precision:

specific slicing: Minimizing Waste and Ensuring Fit: precise product reducing is important for reducing waste and ensuring which the tank elements in good shape alongside one another adequately. Pc-controlled reducing machines can obtain high amounts of precision.

Forming tactics: Shaping the Tank with Precision:

Cold Spinning and incredibly hot Spinning: Shaping the Tank with Management: chilly spinning and incredibly hot spinning are prevalent strategies for forming the tank's conclusion caps. These procedures has to be cautiously managed to guarantee uniform thickness and prevent stress concentrations.

Welding procedures: producing robust and Reliable Joints:

GTAW and SMAW: becoming a member of resources with ability: gasoline tungsten arc welding (GTAW) and shielded steel arc welding (SMAW) are prevalent welding techniques Employed in the manufacturing of expansion tanks. the selection of welding procedure depends upon the components getting joined and the specified weld quality.

warmth procedure: Relieving Stress and maximizing toughness:

put up-Weld warmth procedure: lessening Residual strain: Post-weld warmth treatment method is often made use of To alleviate residual stresses inside the weld joints, bettering the tank's Over-all power and resistance to exhaustion failure.

Environmental elements: being familiar with the Operating ailments

The setting during which an growth tank operates can appreciably influence its lifespan. comprehension these factors and taking appropriate safeguards is essential for maximizing longevity.

Temperature Extremes: Impact on resources and Seals:

substantial Temperature Degradation: deciding on products for Heat Resistance: superior temperatures can accelerate corrosion and degrade the Houses of resources, specially seals and diaphragms. deciding on resources which can be rated for your running temperature is vital.

minimal Temperature Embrittlement: avoiding Cracking in Cold Climates: very low temperatures could potentially cause some resources to be brittle, growing the risk of cracking. This is especially significant in cold climates.

Pressure Fluctuations: Fatigue and pressure on elements:

Cyclical Loading: Designing for Fatigue Resistance: Cyclical strain fluctuations can result in tiredness failure, particularly in areas of superior pressure concentration. planning the tank to resist the predicted force cycles is critical.

Fluid Composition: Compatibility and Corrosion Resistance:

Corrosive Fluids: picking Corrosion-Resistant products: The composition from the fluid currently being dealt with can have a major impact on the tank's lifespan. Corrosive fluids can assault the tank products, leading to leaks or failure. Selecting products which might be appropriate With all the fluid is crucial.

exterior surroundings: safety from The weather:

Outdoor defense: stopping UV Degradation and Corrosion: out of doors exposure can accelerate corrosion and degrade the Attributes of elements, particularly plastics and coatings. safeguarding the tank from the elements by using a weatherproof enclosure is recommended.

the value of servicing: Proactive techniques for Longevity

normal maintenance is important for making sure the very long-time period trustworthiness of expansion tanks. Proactive techniques can identify potential issues early and prevent highly-priced failures.

Regular Inspections: Identifying opportunity issues Early:

Visual Inspection: Checking for Corrosion and injury: common visual inspections can recognize indications of corrosion, leaks, and Actual physical destruction.

stress Testing: Verifying Tank Integrity: Periodic strain testing can verify the tank's integrity and detect any leaks.

Cleaning and Flushing: getting rid of Sediment and particles:

Sediment removing: avoiding Corrosion and Clogging: Sediment and particles can accumulate during the tank, resulting in corrosion and clogging. standard cleaning and flushing can protect against these issues.

changing Worn Components: stopping Failure:

Seal and Diaphragm substitute: protecting program Integrity: Seals and diaphragms are subject to use and tear and may get replaced periodically as Portion of a preventative servicing program.

exterior Coating routine maintenance: defending towards Corrosion:

Coating Inspection and maintenance: protecting against Corrosion unfold: typical inspection and mend from the exterior coating can reduce corrosion from spreading and compromising the tank's structural integrity.

expectations and Certification: making certain Compliance and top quality

Adhering to market criteria and getting certifications are critical for making certain the standard and basic safety of expansion tanks.

structure and producing criteria: Compliance with field Norms:

ASME and PED: Conference Intercontinental specifications: Compliance with business specifications, like ASME (American Society of Mechanical Engineers) and PED (tension tools Directive), makes certain that the tank is built and produced to meet arduous safety and overall performance specifications.

Third-bash Certifications: Verifying high quality and protection:

CE and UL: unbiased Verification of Performance: Third-social gathering certifications, such as CE (Conformité Européenne) and UL (Underwriters Laboratories), deliver independent verification of the tank's high-quality and protection.

The lifespan and durability of enlargement tanks are multifaceted, based on a mix of materials choices, style and design concerns, producing high quality, environmental components, and diligent maintenance. By comprehending these essential factors and applying best techniques, engineers, contractors, and facility administrators can drastically increase the everyday living in their enlargement tanks, reduce operational prices, and make sure the reliable effectiveness of their programs. For those looking for trustworthy and durable enlargement tanks constructed to exacting expectations, take into consideration Checking out alternatives from reputable suppliers like IWM, known for their commitment to top quality and innovation in pressure vessel technology. Their filter tank and filter tank producer track record ensures a stage of expertise you'll be able to rely on.

Val Kilmer Then & Now!

Val Kilmer Then & Now! Joshua Jackson Then & Now!

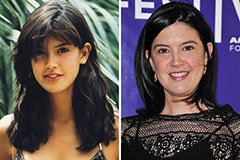

Joshua Jackson Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now!